Specification:

Metal analyzer

CCD-based, spark discharge, optical emission spectrometer

Software-extendable configuration fro utmost elemental flexibility

Ultra-low limits of detection

Ultra-high speed of measurement

Long-term stability and repeatability

Excellent vertical optical emission spectroscopy

Summary:

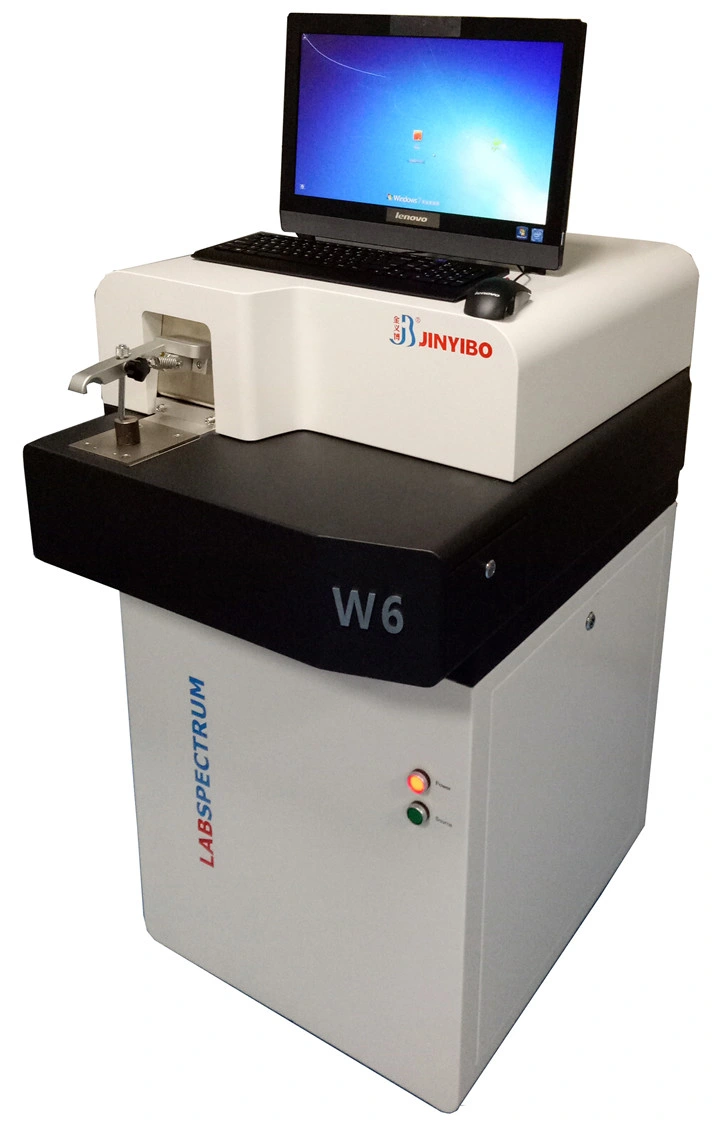

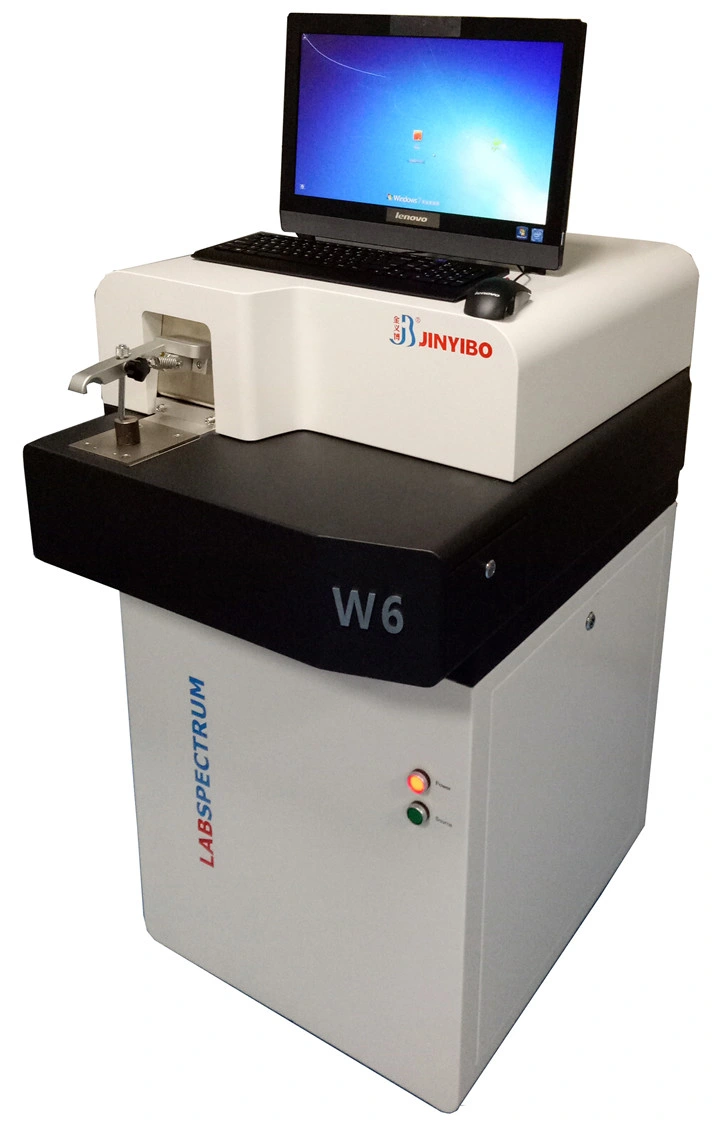

W6-The most advanced Arc/Spark-OES with Ultimate Performance for Metal Analysis. It use full-digital technology to replace bulky photomultiplier tube (PMT) simulation technology and in the lead of international spectrometer technology. The adoption of vacuum optical chamber design, full-digital excitation light source, advanced CCD detectors, and high-speed data readout system equips the device with high properties, ultra-low limit of detection (LOD), long-term stability and repeatability. Its analytical precision reaches the world leading level. It is one of the major devices that applies to quality control, material brand recognition, material research and development in the metallic manufacturing, processing and smelting industry. This analyzer sets a new standard for R&D and process/quality control.

Applications:

W6 optical emission spectrometers(spark OES) as one of the major devices that applies to quality control, material brand recognition, material research and development in the metallic manufacturing, processing and smelting industry.W6 are used for applications in metal elemental analysis, trace element analysis for science and industry like Metallurgy, Foundry, Mechanical Engineering, Scientific Research, Product Inspection, Automobile, Petrochemical Engineering, Shipbuilding, Electrics, Aerospace, Nuclear Power, Metallic and Nonferrous Metallic Smelting, Processing and Recycling.

High-end Laboratories Defence, Railways, pure research, etc.

Pure metal applications 99.9%+ purity Al, Pb, Zn, Mg etc.

Regulatory compliance Very low LODs to control Pb, Cd, As etc. (e.g. ship-making)

Integrated Steel Plants C, S, P, B, N, Ti;

Manufacturing Facilities

Warehouse material identification

Base: Fe, Cu, Al, Ni, Co, Mg, Ti, Zn, Pb, Sn, Ag etc

Iron(Fe) and its alloys (Steel alloy, Cast iron, Fe-Low alloy, Fe-Cr steel, Fe-Cast iron, Fe-Cr-cast, Fe-Mn steel, Fe-Tool steel etc.)

Aluminium(Al) and its alloys (Al-Si alloy, Al-Zn alloy, Al-Cu alloy, Al-Mg alloy, Pure-Al alloy etc)

Copper(Cu) and its alloys (Brass, Copper-Nickel-Zn, Aluminum Bronze, Tin-lead Bronze, Red Copper, Be-Bronze, Si-Bronze etc)

Nickel(Ni) and its alloys (Pure Ni, Monel metal, Hadtelloy Alloy, Incoloy, Inconel, Nimonic etc)

Cobalt(Co) and its alloys (Co-orientation, Low Co alloy, Stellite 6,25,31, Stellite 8,WI 52, Stellite 188, F)

Magnesium(Mg) and its alloys (Pure Mg, Mg/Al/Mn/Zn-alloys)

Titanium(Ti) and its alloys

Zinc(Zn) and its alloys

Lead(Pb) and its alloys

Tin(Sn) and its alloys

Argentum(Ag) and its alloys

Small sample, special size sample and wire detection

Parameter:

Packing & Shipping

Metal analyzer

CCD-based, spark discharge, optical emission spectrometer

Software-extendable configuration fro utmost elemental flexibility

Ultra-low limits of detection

Ultra-high speed of measurement

Long-term stability and repeatability

Excellent vertical optical emission spectroscopy

Summary:

W6-The most advanced Arc/Spark-OES with Ultimate Performance for Metal Analysis. It use full-digital technology to replace bulky photomultiplier tube (PMT) simulation technology and in the lead of international spectrometer technology. The adoption of vacuum optical chamber design, full-digital excitation light source, advanced CCD detectors, and high-speed data readout system equips the device with high properties, ultra-low limit of detection (LOD), long-term stability and repeatability. Its analytical precision reaches the world leading level. It is one of the major devices that applies to quality control, material brand recognition, material research and development in the metallic manufacturing, processing and smelting industry. This analyzer sets a new standard for R&D and process/quality control.

Applications:

W6 optical emission spectrometers(spark OES) as one of the major devices that applies to quality control, material brand recognition, material research and development in the metallic manufacturing, processing and smelting industry.W6 are used for applications in metal elemental analysis, trace element analysis for science and industry like Metallurgy, Foundry, Mechanical Engineering, Scientific Research, Product Inspection, Automobile, Petrochemical Engineering, Shipbuilding, Electrics, Aerospace, Nuclear Power, Metallic and Nonferrous Metallic Smelting, Processing and Recycling.

High-end Laboratories Defence, Railways, pure research, etc.

Pure metal applications 99.9%+ purity Al, Pb, Zn, Mg etc.

Regulatory compliance Very low LODs to control Pb, Cd, As etc. (e.g. ship-making)

Integrated Steel Plants C, S, P, B, N, Ti;

Manufacturing Facilities

Warehouse material identification

Base: Fe, Cu, Al, Ni, Co, Mg, Ti, Zn, Pb, Sn, Ag etc

Iron(Fe) and its alloys (Steel alloy, Cast iron, Fe-Low alloy, Fe-Cr steel, Fe-Cast iron, Fe-Cr-cast, Fe-Mn steel, Fe-Tool steel etc.)

Aluminium(Al) and its alloys (Al-Si alloy, Al-Zn alloy, Al-Cu alloy, Al-Mg alloy, Pure-Al alloy etc)

Copper(Cu) and its alloys (Brass, Copper-Nickel-Zn, Aluminum Bronze, Tin-lead Bronze, Red Copper, Be-Bronze, Si-Bronze etc)

Nickel(Ni) and its alloys (Pure Ni, Monel metal, Hadtelloy Alloy, Incoloy, Inconel, Nimonic etc)

Cobalt(Co) and its alloys (Co-orientation, Low Co alloy, Stellite 6,25,31, Stellite 8,WI 52, Stellite 188, F)

Magnesium(Mg) and its alloys (Pure Mg, Mg/Al/Mn/Zn-alloys)

Titanium(Ti) and its alloys

Zinc(Zn) and its alloys

Lead(Pb) and its alloys

Tin(Sn) and its alloys

Argentum(Ag) and its alloys

Small sample, special size sample and wire detection

Parameter:

| Item | Index | |

| Optical System | Focal Length | 400nm |

| Wavelength range | 130nm-800nm | |

| Detector | High resolution CCD Multi detectors | |

| Degree of vacuum | Auto control within 6-20 pa | |

| Pixel resolution | 30pm | |

| Grating line | 2400m1/mm | |

| First order spectral line dispersion rare | 1.2nm/mm | |

| Average resolution ratio | 10pm/pixel | |

| Full spectrum | ||

| Light room temperature is controlled automatically | ||

| Spark Source | Type | Digital arc and spark source |

| Spark frequency | 100-1000HZ | |

| Plasma current | 1-80A | |

| Ignition voltage | >15000V | |

Excitation light | Optimization of discharge parameters design | |

| High energy precombustion technology HEPS | ||

Processor | High-speed data synchronization acquisition and processing | |

| Spark Stand | Electrode | Tungsten electrode technology |

| Make up | Thermal deformation self-compensation design | |

| Argon flushed with minimal consumption of Argon | ||

| Spray discharge electrode technology | ||

| Adjustable electrode technology | ||

| Others | Measurable elements | Fe,Al,Cu,Ni,Ti,Co,Zn,Sn,Mg,Pb etc |

| Dimension | 650mm(L)*860mm*1200mm(H) | |

| weight | About 235kg | |

| Storage temperature | 0ºC-45ºC | |

| Operating temperature | 10ºC-35ºC, 23±2ºC is recommended | |

| Power | AC220V/50Hz(Customized) | |

| Power consumption | Excitation:700W/Stand by:100W | |

| Argon quality | 99.999%, Argon pressure>4Mpa | |

| Argon consumption | 5L/min during spark mode | |

| Interface | Ethernet data transmission based on DM9000A | |

Packing & Shipping